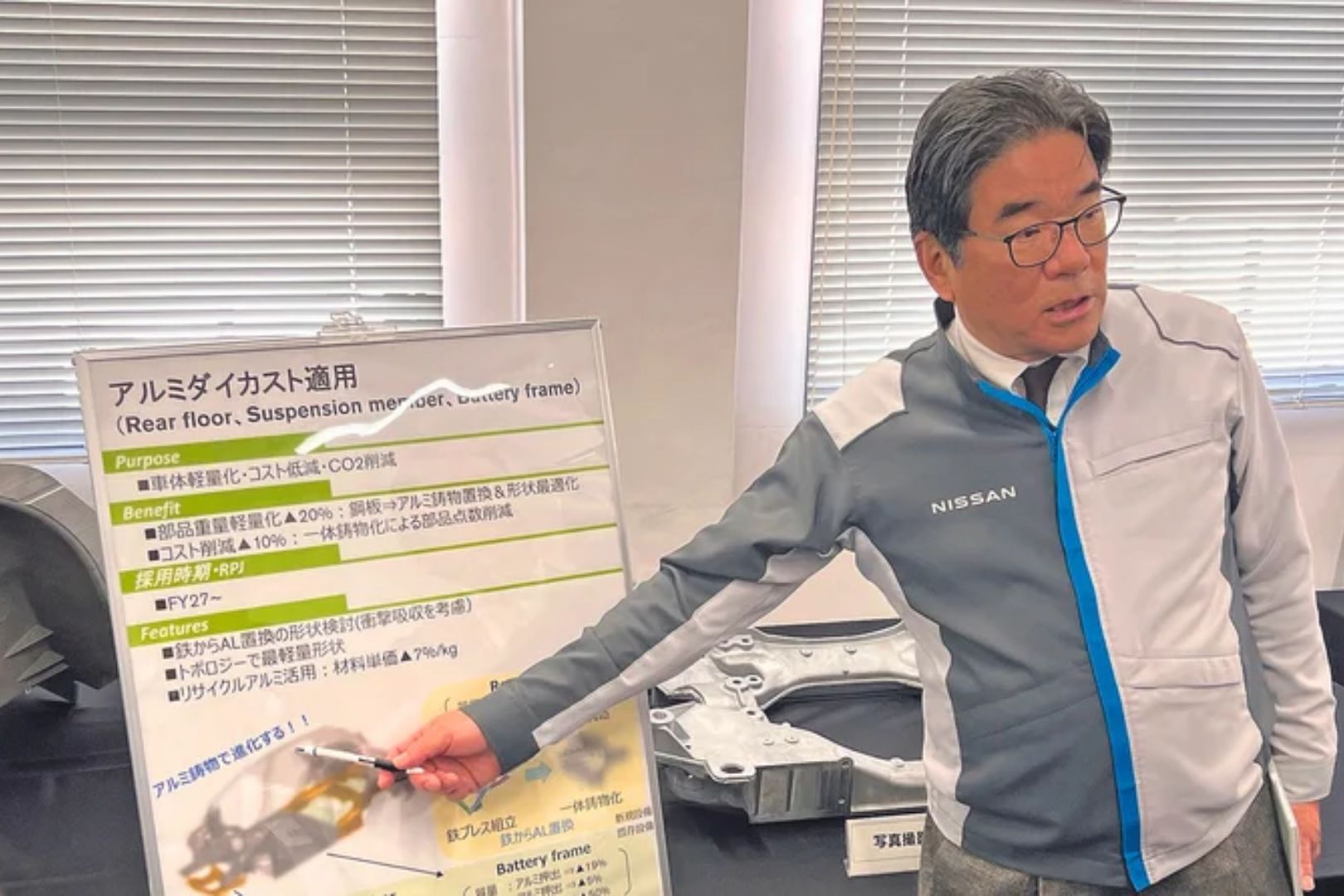

Nissan is set to revolutionize its manufacturing process by adopting giga-casting technology worldwide by 2027. This strategic move will lower production costs by 30 per cent, translating to an estimated Rs. 1000cr in savings for developing five upcoming car models.

Giga-casting is making large and complicated casting structures in a high-pressure die-casting machine that injects molten aluminium into casting moulds. In a motoring sense, these moulds would be the chassis, bolt-ons or any other part.

Adopting giga-casting could have profound implications for the Indian automotive industry. As a rapidly growing market with a strong focus on cost efficiency and sustainability, India stands to benefit from this technology. Reduced manufacturing costs can lead to more affordable vehicle prices for consumers, making advanced automotive technology accessible to a broader audience.

Giga-casting aligns with India’s environmental goals by minimizing waste and energy consumption in manufacturing as the country pushes towards greener automotive solutions.