Photographs by Eurogrip

In a world where displacement, power and torque numbers hog the spotlight, the most crucial piece of the puzzle usually slips under the radar — tyres. Think about it, that tiny patch of rubber, not much bigger than an A4 sheet, is all that connects you and your motorcycle to the road. Yet it dictates how much of that performance you actually get to enjoy.

Over the years of riding different bikes, I’ve never really taken the time to think about tyres in detail. What goes into the rubber mix? How do they come up with tread patterns? Why do some use steel belts and others nylon? The more you think about it, the more questions you end up with. And for me, that curiosity has always been there, because tyres are the only real connection we have with the road.

So when the invite came to attend the ninth edition of Eurogrip Tread Talks, an event where journalists get to watch tyres being born and then flog them in the real world, I was all in. For me, it wasn’t just about the factory tour; it was also the perfect excuse to dust off my riding gear and head out on a motorcycle trip after what felt like forever.

But before I could swing a leg over the bike, our first stop was Eurogrip’s factory in Madurai. Walking through those gates felt less like stepping into an industrial setup and more like sneaking behind the curtain at a magic show. From raw sheets of rubber to gleaming finished tyres, the process was equal parts meticulous and mesmerising. And here’s the kicker, Eurogrip isn’t just making tyres for India. Their products roll into Indonesia, Thailand, Colombia, and soon, the American market, too, with tyres tailor-made for cruisers like Harley Davidson and Indian Motorcycle.

Out of everything inside the factory, it was the R&D facility that really knocked me sideways. Sivaramakrishnan V, Eurogrip’s CTO, casually mentioned that they can strip down any tyre to its molecules and analyse every single detail before it even hits production. And just when I thought I’d seen it all, Eurogrip rolled out some eye candy, a set of racing slicks for superbikes. These are headed to the TVS India One Make Championship, with a market launch targeted for 2027 to take on the mighty Pirelli Supercorsa SP V4. On the saner side of things, they also showed off the Roadhound, their entry-level big bike tyre, now available in its widest 190-section.

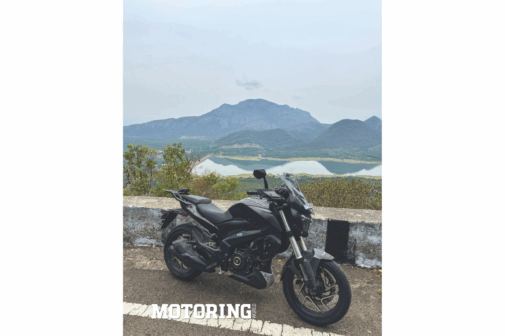

With the briefing done, it was finally time to ride. A line of motorcycles stood waiting, each one kitted with Eurogrip’s freshest rubber. I started off on the Hero Xtreme 160R, running ATT230s at the front and ProTorq Extremes at the rear. Day two, I switched to the Bajaj Dominar 400, this time with ProTorqs at both ends. The fleet was a mixed bag — light, sporty commuters like the Yamaha FZ-S, Suzuki Gixxer 150, Hero Xtreme 125R, and for those who prefer a dash of old-school, the Royal Enfield Classic 350.

The ride plan was just right — a 200-km stretch from Madurai up to Kodaikanal. Funnily enough, I’d driven up those same twisties a few months ago in a car, but two wheels changed the game entirely. The route had everything, snaking bends, surprise rain showers, and a steady climb in altitude. In short, the perfect playground to see what a set of tyres is really made of.

The ride up to Kodai itself was largely uneventful, but the tyres shone, letting me attack corners and skim over rough patches with confidence. The only hiccup was the Xtreme 160R, which developed a stubborn clutch issue that robbed me of some fun. Still, I wasn’t about to sulk. With the tyres gripping like glue, I ended up pushing harder and wringing out every bit of performance the bike still had to give.

For the return leg the next morning, my plan was simple: get a proper feel of the ProTorq Extremes I’d been hearing so much about. But the weather gods clearly had a sense of humour. The moment we rolled out of Kodaikanal, the skies opened up and I was riding through a torrential downpour… with zero rain gear. Within minutes, I was soaked to the bone, half cursing myself and half wondering if Eurogrip also made waterproof jackets.

If there was ever a way to test tyres, though, this was it. And to their credit, the ProTorqs didn’t f l inch. Through puddles, slick roads, and blind bends, they just gripped and carried on. Even as one of the greener riders in the group, I kept pace without once feeling sketchy — and honestly, that kind of reassurance in the wet is worth its weight in gold.

By the time the tour wrapped up, I had a newfound respect for tyres. They’ve always been the last thing I’ve looked at when testing a vehicle, but a day inside the factory and nearly 400 km on the road drove the point home. All the power and torque numbers in the world mean nothing if you don’t have good rubber underneath. Without it, everything else is just brochure talk.